| Description | The KAISER HFR 8000 Frame Tracer is where efficiency meets versatility, providing efficiency that today’s retail practices require.

The HFR-8000 is part of the widely-acclaimed KAIZER line. KAIZER is the next generation to follow the Huvitz Excelon series and is designed with a wide array of features intended to simplify and perfect in-house lens finishing. The HFR-8000 is a fully automatic frame tracer that performs 3-dimensional tracing. This material-friendly unit can be used in virtually every situation. It provides fast and adaptable tracing for all frame materials and shapes. In fact, it is capable of scanning and digitally filtering 16,0000 points of shape data. The HFR-8000 also features Huvitz Mechatronic Technology. This built-in stereoscopic scan technology provides accurate tracing even on high curve frames. The HFR-8000 is a perfect accompaniment to the HPE-8000 Edger and offers flexibility, precision and quality that can’t be beat. | Complete Control of Lens Mounting

- Optimal monitoring of all trajectories, irrespective of finishing materials or shapes

- Absolute axis control thanks to hybrid edging technology: grinding + milling

- Ideally suited for quality finishing even on highest base curves

- Fast and accurate drilling with data acquired in a single operation

- Automatic centering and blocking for simple operation

| Features- NEW TruFit 3D Virtualization allows you to simulate the lens inside the frame before edging, allowing you to minimize retouches and maximize your profit.

- One of the fastest lens edgers on the market.

- Process nearly any job type to avoid having to send out costly jobs to labs.

- Superior quality of finish and polish provides a premium look and feel that you can be proud of.

- Smart Design shape customization.

Wavefront Power-mapping technology for lens analysis and verification.

- Shelf Bevel to easily process high base-curve wrap frames.

- TruScan High base curve frame tracing

| Features of the HDM-8000 Drilling Unit| ▪ Data Profiling Algorithm

▪ Smart Job Manager Software

▪ Easy Hole Editing

▪ Single Click Simplicity | ▪ Accommodates Anything

▪ Advanced Safety Features

▪ Small Footprint

▪ Promotes Cleanliness |

| | | Data Profiling Algorithm

The HDM-8000 features a new systematic data-profiling algorithm that significantly reduces job-processing time. | |  | | Smart Job Manager Software

With Smart Job Manager software, the HDM-8000 allows you to process and cut your next lens while drilling is in process. |

| The edger KAIZER HPE-8000X – for a fast and precise lens processing.Functions and characteristics:

– Minimising the risk of axis torsion

– Few grinding dust

– Exactly adjustable mini bevel

– Partial grooving

– Partial step bevel

– Hybrid bevel for the combination of groove and bevel on one lens

– Exactly adjustable position of bevel and groove in 0.01 mm steps

– Powerful and durable direct drive motor for the grinding wheels

– Fast | The Huvitz Excelon CPE-4000 Edger is a versatile lens finishing system designed for retail practices. All of the finishing processes—from tracing to edging—are fully optimized with advanced three-dimensional digital technology, enhancing productivity and efficiency.

Beveling, polishing, grooving and safety beveling are completely integrated and easily performed by a touch of a button. In addition, built-in the CPE-4000 features digital pattern layout that allows users to modify shape width, height, and circumference to better manage the fitting challenges posed by rimless and semi-rimless frames. |

| Content | Huvitz HFR-8000 Frame Tracer

The KAISER HFR 8000 Frame Tracer is where efficiency meets versatility, providing efficiency that today’s retail practices require.

The HFR-8000 is part of the widely-acclaimed KAIZER line. KAIZER is the next generation to follow the Huvitz Excelon series and is designed with a wide array of features intended to simplify and perfect in-house lens finishing. The HFR-8000 is a fully automatic frame tracer that performs 3-dimensional tracing. This material-friendly unit can be used in virtually every situation. It provides fast and adaptable tracing for all frame materials and shapes. In fact, it is capable of scanning and digitally filtering 16,0000 points of shape data. The HFR-8000 also features Huvitz Mechatronic Technology. This built-in stereoscopic scan technology provides accurate tracing even on high curve frames. The HFR-8000 is a perfect accompaniment to the HPE-8000 Edger and offers flexibility, precision and quality that can’t be beat.Huvitz HFR-8000 Frame Tracer| racing Type | Automatic 3D Binocular Tracing | | | | Tracing Mode | Auto, Semi-Auto | | | | Tracing Size | Frame ø0.7~3.7in (ø16.0~92.0mm), pattern ø0.7~3.3in (ø16.0~84.0mm) | | | | Frame Material | Metal, Hard Plastic, Soft Plastic | | | | Data Processing | FPD, Frame Curve, Circumference, 3D Angle Concave Shape | | | | Dimensions / Weight | 11.2(W) x 13(D) x 7.5(H)in / 17.6lb (284(W) x 320(D) x 190(H)mm / 8kg) | | | | Power Supply | 100 – 240V, 50 / 60Hz | | | | Power Consumption | 32W |

Features of the HFR-8000 Frame Tracer| ▪ Automatic 3-Dimensional Tracing

▪ Stereoscopic Scan Technology

▪ Material-Friendly

▪ Works With Any Shape | ▪ 16,000 Data Points

▪ Mode Options

▪ Real-Time Data

▪ Dust Free |

| | | Automatic 3-Dimensional Tracing

The HFR-8000 is a fully automatic frame tracer that performs 3-dimensional tracing. | |  | | Stereoscopic Scan Technology

The HFR-8000 features Huvitz Mechatronic Technology. This built-in stereoscopic scan technology provides accurate tracing even on high curve frames. | |  | | Material-Friendly

The HFR-8000 is a material-friendly unit that can be used in virtually every situation. It provides fast and adaptable tracing for all frame materials. | |  | | Works With Any Shape

With this KAIZER-line frame tracer, you can accurately scan concave sand narrow frames as well as frames with sharp edges. | |  | | 16,000 Data Points

One of the reasons the HFR-8000 is so versatile and accurate is because it is capable of scanning and digitally filtering 16,0000 points of shape data. | | | Mode Options

Enjoy complete flexibility with this outstanding tracing unit. Users can select form left-eye, right-eye or complete tracing modes. | |  | | Real-Time Data

With the HFR-8000, there’s no more waiting for data to upload. This unit features Real-Time automatic data transfer to the edger. | | | Dust Free

The HFR-8000 comes with it’s own slide cover to prevent dust accumulation. |

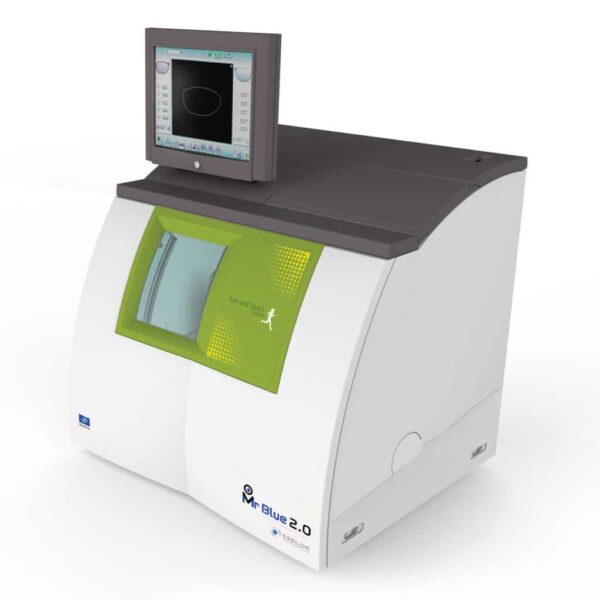

| Essilor Mr Blue 2.0 Sun & Sport Edition Patternless EdgerFrom Essilor Instruments, Mr Blue Sun & Sport Edition edging system expands your offer:- Produce Chemistrie clips as custom-made sunwear

- Achieve Half Jacket frame coverage for endurance and extreme sports

“Sun & Sport Edition” and its special features are available for every “Mr Blue Sun & Sport Edition” edger order, associated with a new orChemistrie clips :- Generate additional revenues through an alternative to both prescription sunwear and unsatisfactory clip-on sets..

- Magnetic lens layering system: a patented technology that attaches lenses to virtually any prescription eyewear using magnets embedded in the lenses.

- Base curve matched, lightweight, custom made.

Half Jacket frames : Essilor Mr Blue 2.0 Sun & Sport Edition Patternless Edger- Capitalize on the rising popularity of endurance and extreme sports.

- Achieve a wider frames coverage with the partial step bevel inn addition to full high curve, asymmetric bevel, and step bevel.

- A dedicated process and assistance on your machine supported by new tools.

already owned Mr Blue Tracer or Mr Orange Tracer.Mr Blue 2.0 is on the cutting edge of innovation – serving as a genuine ECP partner since its launch. Now featuring a whole range of new functions and even greater flexibility than before, Mr. Blue 2.0 is the perfect solution for:- Working with cutting-edge technology

- Differentiating your offerings

- Optimizing your edging process

- Manufactured by Essilor | CE- and UL-certified

Chemistrie Clips to Bring You a New Innovative Sun Offer- Generate additional revenues through an alternative to both prescription sunwear and unsatisfactory clip-on sets

- Magnetic lens layering system: a patented technology that attaches lenses

to virtually any prescription eyewear using magnets embedded in the lenses

- Base curve matched, lightweight, and custom made

- A specifically-designed process on Mr Blue Sun & Sport Edition together with available materials and support

Half Jacket Frames to Excel in Your Sports Offer- Capitalize on the rising popularity of endurance and extreme sports

- Achieve a wider frames coverage with the partial step bevel(1) in addition to full high curve, asymmetric bevel, and step bevel

- A dedicated process and assistance on your machine supported by new tools

(1) Bevel a portion of the thick lens edge into a step to fit into frames so that only a part of the edge is inserted, and protrusions on the lens hook into indentations in the frame groove | Briot Couture Lens Finishing System

When your standards are high, this is the partner you deserve. A revolution in edging, Briot Couture gives you a flawless finish with every frame – whatever the style, shape or curve. 3D pre-visualization lets you see your results before you even start working. TrueFit technology calculates curvatures to ensure seamless lens-frame pairing. Additionally, new sensors coupled with advanced software maintain constant pressure on the lens, reducing cycle time with no risk of misalignment – especially on hydrophobic lenses.Wavefront, The Future Of Blocking Briot Couture Lens Finishing System Our exclusive wavefront lens analysis allows you to see progressive lens designs on the frame trace before you even cut the lens, giving you the opportunity to validate that the shape and lens design are compatible without wasting time or money redoing the job. Shape Creation Limited Only By Your Imagination With Smart Design Milling And Shelf Beveling Create complex shapes and a true shelf bevel for high base-curve wrap frames with the Smart Design Milling feature in the Briot Couture. Exclusive TrueScan High-Curve Tracing Featuring our patented TrueScan technology, the Attitude Tracer/Blocker has a specially designed angled probe that will gently measure the contour of even the thinnest, most delicate metal frames or high base-curve wrap frames effortlessly. Brushless Technology For Faster, Quieter Operation Edge lenses faster and more efficiently while also reducing noise with new brusheless motor technology featured on the Evolution. Now, you can plug this edger in anywhere that has a 120V line adding extra placement flexibility in your optical lab. Provide The Best Finish On High Base-Curve Frames With Briot’s Best-Fit Technology Our advanced drive technology in conjunction with a small 90mm diamond wheel allows flawless finishing on high base-curve lenses and complex frames with sharp corners. Damaged Demo Lens? No Problem With Shape Creator 2.0 Accurately reconstruct broken or defective demo lenses with minimal effort using the new Shape Creator 2.0 technology on the Couture Blocker. | Huvitz Kaizer HDM-8000 Drilling Unit

The KAIZER line is the next generation to follow the Huvitz Excelon series and is designed with a wide array of features intended to simplify and perfect in-house lens finishing.

The HDM-8000 Drilling Unit offers the ultimate time saving solution to increase your profitability. You can transmit jobs with a single click. Create the wildest lens shape imaginable. Virtually any shape lens and hole pattern is attainable. The HDM-8000 also features a sleek design and a small footprint that can fit beautifully in any space.| Hole Type | Hole, Slot, Notch | | | | Hole Size | ø0.04~0.4in (ø1.00~10.00mm) | | | | Frame Material | Metal, Hard Plastic, Soft Plastic | | | | Tilting Scope | Automatic, Manual (0~30°) | | | | Hole Depth | Max 0.24in/6.0mm (0.0mm = Through Hole) | | | | Slot Width | 0.04in ~ 0.16in (1.00mm ~ 4.00mm) | | | | Slot lenght | Max 0.8in / 20.00mm | | | | Dimension / Weight | 7.6(W) x 19(D) x 13.5(H)in / 30.8lb (193(W) x 483(D) x 342(H)mm / 14kg) | | | | Power Supply | 100 – 240V, 50 / 60Hz | | | | Power Consumption | 100W |

The KAIZER line is the next generation to follow the Huvitz Excelon series and is designed with a wide array of features intended to simplify and perfect in-house lens finishing.The HDM-8000 Drilling Unit offers the ultimate time saving solution to increase your profitability. You can transmit jobs with a single click. Create the wildest lens shape imaginable. Virtually any shape lens and hole pattern is attainable. The HDM-8000 also features a sleek design and a small footprint that can fit beautifully in any space.Features of the HDM-8000 Drilling Unit

▪ Data Profiling Algorithm

▪ Smart Job Manager Software

▪ Easy Hole Editing

▪ Single Click Simplicity

▪ Accommodates Anything

▪ Advanced Safety Features

▪ Small Footprint

▪ Promotes CleanlinessData Profiling Algorithm

The HDM-8000 features a new systematic data-profiling algorithm that significantly reduces job-processing time. | Huvitz KAIZERX HPE-8000X edger | HUVITZ CPE 4000 3D Edger Patternless EdgerFeatures of the CPE-4000 Patternless Edger| ▪ Digital Pattern Layout

▪ Frame Comparison

▪ Advanced Digital Technology

▪ Four Grinding Wheels

▪ 3D Lens Measurement

▪ Ultra-Fine Bevel Adjustment | ▪ Automatic Polishing

▪ Safety Bevel

▪ Adjustable Precision Grooving

▪ Convenient User Interface

▪ More Efficient

▪ Silent Operation |

| |  | | Digital Pattern Layout

The Digital Pattern Layout function allows users to modify lens width, height, and circumference and manage the fitting challenges posed by rimless and semi-rimless frames. You can can choose between optical and geometric centered layouts. Layouts for far vision and near vision in bifocal lens mode are provided. The horizontal PD can be easily adjusted and multiple input methods for setting the height of multifocal progressive lenses are available. | | HUVITZ CPE 4000 3D Edger Patternless Edger | | Frame Comparison

When replacing frames the sizes of the old and new frames can be conveniently compared on screen. Advanced Digital Technology

Advanced 3-Dimensional digital technology substantially reduces the overall cycle time.Four Grinding Wheels

The CPE-4000 edger features four grinding wheels, enabling you to work with all lens materials including glass, plastic, hi-index, polycarbonate, and Trivex. | |  | | 3D Lens Measurement

The CPE-4000 features an advanced lens sensor that will allow you to achieve a 3-dimensional measurement to optimize both beveling and grooving. | |  | | Ultra-Fine Bevel Adjustment

With the CPE-4000, bevel position can be precisely adjusted in fine 0.01mm increments relative to the front curve, back curve, thickness, or base curve of the lens. | | | Automatic Polishing

Enjoy superior, automatic polishing of beveled, grooved, and flat-edged lenses. | |  | | Safety Bevel

The CPE-4000 can achieve front and rear safety beveling, making it a leader in its class. | | | Adjustable Precision Grooving

This model features incredibly fine, adjustable precision grooving. The position, width and depth of the groove can be adjusted in 0.01mm increments. | |  | | Convenient User Interface

A graphic user interface makes it easy for virtually any operator to manage all of the process functions and custom settings. | | | More Efficient

Numeric keypad permits rapid data entry. With the CPE-4000, you can manage multiple jobs simultaneously for improved efficiency. Silent Operation

A built-in inverter mechanism minimizes noise during the edging process, ensuring a comfortable work environment. |

| Edging System | Automatic | | | | Edging Mode | Beveling

Flat Edging

Grooving

Safety Beveling

Polishing | | | | Lens | Glass, Plastic, High Index Plastic, Poly Carbonate, Trivex | | | | Edging Size | Max: 3.54in / 90mm

Min: 0.71in / 18mm | | | | Weight | 99lb / 45kg | | | | Power Supply | AC 110/220V, 50/60Hz | | | | Power Consumption | 1200W (Max) | | | | Dimension | 22.44(W) X 21.26(D) X 18.11(H)in (570(W) X 540(D) X 460(H)mm) | | | | Others | High Brightness Wide TFT LCD Adopted

Bar Code System Available

Networking System | | | | Tracer | | | | Dimension | 11.02(W) X 11.81(D) X 9.05(H)mm (280(W) X 300(D) X 230(H)mm) | | | | Tracing System | 3D Binocular | | | | Weight | 17.6lb / 8kg | | | | Power Supply | AC 110/220V, 50 / 60Hz | | | | Power Consumption | 42W (Max) | | | | Others | User friendly display with LCD |

|

Reviews

There are no reviews yet.